Chemical Management: Maximum Allowable Quantities (MAQ) Resources

Chemical Management:

Maximum Allowable Quantities (MAQ) Resources

Senior Leadership at The University of California Office of the President (UCOP) convened the Maximum Allowable Quantities (MAQ) Chemical Task Force to evaluate the current MAQ status at each location, develop solutions and pathways to compliance, and create educational resources. Guidance provided here exists as draft material that your campus or location can access, edit, and repurpose for your educational and training needs. This webpage will be updated as more resources become available.

Overview

Maximum allowable quantities (MAQs) per control area. The maximum amount of hazardous material allowed to be stored or used within a control area inside a building or an outdoor control area. The California Fire Code (CFC) and California Building Code (CBC) establish these limits, which are broken down by hazard class and physical state (solid, liquid, or gas). Compliance with Fire Code hazardous materials regulations ensures that the minimum level of fire and life safety is met for building occupants and first responders.

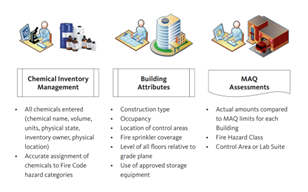

Determining MAQs relies on many factors, including:

- Quantities of hazardous materials

- Types of hazardous materials

- Physical state of hazardous materials

- Method of storage and use

- Occupancy type

- Building and construction attributes

- Building ventilation and automatic fire suppression system (sprinklers)

Control Areas

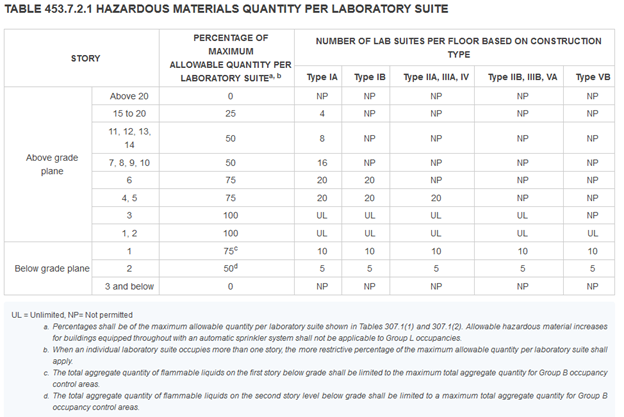

A space within a building where quantities of hazardous materials not exceeding the maximum allowable quantities (MAQs) per control area are stored, dispensed, used, or handled. Control areas can be indoors or outdoors. A single control area can span an entire building, floor, room, or contiguous suite of rooms. However, they must be separated from other control areas by fire-resistance rated construction.

- Must be separated from each other by fire-resistance rated barriers on all six sides (floor, ceiling, 4 walls)

- Number of control areas allowed and MAQs per control area vary with floor level, sprinkler status, and storage conditions of chemicals

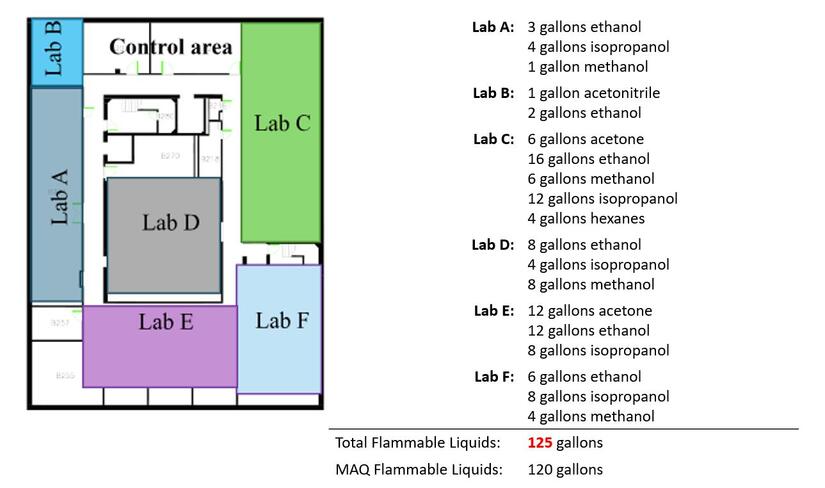

- Lab A + Lab B + Lab C + … Lab X = TOTAL Control Area MAQs

Specifications

-

Building Attributes

Building Attributes

Code of record for when building was constructed:

In California, the Building Code is updated every three years with changes and new requirements. Currently, the California Building Code (CBC) and California Fire Code (CFC) are based on the International Code Council (ICC)’s family of codes, while the California Mechanical Code (CMC) is based on the Uniform Mechanical Code (IAPMO). These codes work as companions to each other. For example, the CBC designates how a building shall be constructed, while the CFC provides requirements for fire and life safety features, including the storage, handling, dispensing and use of hazardous materials. For more on the history of the Building code in the U.S.A., see article here (History of Codes in USA).

Construction and design provisions of the CBC and CFC typically only apply to new construction, so that older buildings that were compliant at the time of construction do not have to be upgraded constantly. However, administrative, operational, and maintenance provisions of the CFC apply to both new construction and existing conditions and operations. Hazardous materials storage, dispensing, and use is generally considered operational and therefore must adhere to the current version of the CFC. There is an exception for buildings constructed prior to 2008, where the older control area concept is permitted (see California OSFM bulletin).

Occupancy type:

See section describing different occupancies in California. The California Building Code (CBC) outlines how a building or portion of a building must be constructed depending on the occupancy classification. Building attributes, such as sprinkler coverage and density, fire-resistance rated elements, ventilation, exiting, separation from other occupancies is less restrictive in certain occupancy types, such as Group B, compared to Group L or Group H. If certain types of hazardous materials are being stored or used in excess of MAQs, this triggers Group H, High Hazard occupancy requirements. The Building Code would dictate how this was built. For example, High hazard, Group H-2 occupancies contain flammable atmospheres (due to high quantities (>MAQ) of flammable gases or flammable liquids in open use). These occupancies must meet additional structural, separation, electrical, fire safety and other provisions to safely store these types of materials.

Fire-resistant rated construction:

Chapter 7 of the California Building Code outlines the fire-resistance rating requirements for different building elements. These either meet specific fire exposure test criteria (specified in ASTM E119 or UL263), prescriptive requirements, results of an engineering analysis, or another method approved by the Fire Marshal.

Control areas must be separated from other control areas by fire barriers or fire walls. Some occupancies are also required to have separation by fire barriers. The level of fire-resistance rated separation (1-hr, 2-hr, etc…) depends on the floor level relative to grade plane, adjacent occupancies, and occupancy type.

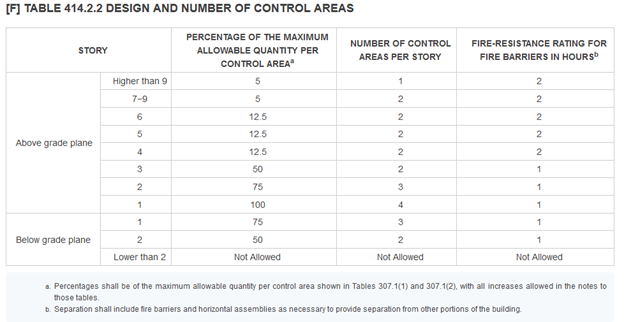

For example, control areas must be separated by 1-hr fire barriers if they are located on the first floor, but they need to be separated by 2-hr fire barriers on the fourth floor (CFC Table 414.2.2)

Fire-resistance rating required to separate occupancies is outlined in CBC Table 508.4.

Floor level relative to grade plane:

Grade plane and other related definitions are provided below from the California Building Code (CBC). Grade plane can be considered the “ground level”, though it can be complex if a building is on a slope (see example CBC Commentary Figure 202(7). Determining the “first floor” (or first story above grade plane) is important, as the MAQs permitted on each floor differ dramatically relative to grade plane.

See CBC Table 414.2.2 for percent reductions in total MAQs for floor levels relative to grade plane. There is a significant drop in MAQ percentage above the third floor, which reflects the maximum height of many fire apparatus vehicles. Evacuation is also more difficult from upper floors of a building during emergencies, therefore it is not considered safe for occupants and first responders to have high chemical quantities on upper floors.

Basement. A story that is not a story above grade plane.

Grade plane. A reference plane representing the average of finished ground level adjoining the building at exterior walls. Where the finished ground level slopes away from the exterior walls, the reference plane shall be established by the lowest points within the area between the building and the lot line or, where the lot line is more than 6 feet (1829 mm) from the building, between the building and a point 6 feet (1829 mm) from the building.

Mezzanine. An intermediate level or levels between the floor and ceiling of any story and in accordance with Section 505.

Story. That portion of a building included between the upper surface of a floor and the upper surface of the floor or roof next above (See Basement, Building height, Grade plane and Mezzanine). A story is measured as the vertical distance from top to top of two successive tiers of beams or finished floor surfaces and, for the topmost story, from the top of the floor finish to the top of the ceiling joists or, where there is not a ceiling, to the top of the roof rafters.

Story above grade plane. Any story having its finished floor surface entirely above grade plane, or in which the finished surface of the next floor above is:

- More than 6 feet (1829 mm) above grade plane; or

- More than 12 feet (3658 mm) above the finished ground level at any point.

Automatic fire suppression system (sprinklers):

Buildings that have automatic fire suppression systems (automatic fire sprinklers or approved alternatives to water-based fire suppression systems) improve life safety. If there is a fire in one section of a building, the fire suppression system is typically designed to control the fire long enough for building occupants to safely evacuate. In a hypothetical 5-story building (below), a fire on the third floor can rapidly spread to upper floors and adjacent rooms, filling them with smoke and fire, and thereby preventing safe evacuation. Full sprinkler coverage throughout the building can keep the fire contained to the room of origin, allowing building occupants to safely evacuate, even from adjacent rooms and floors. This is particularly true when fire resistant rated construction is present in corridors and other parts of the building.

Because of the added level of life safety when sprinklers are installed throughout the building, most hazardous materials can be increased in fully-sprinklered buildings. For Flammable liquids, for example, the amount (MAQ) can be doubled when stored in fully sprinklered buildings for most occupancy types.

Ventilation:

Mechanical ventilation is an important factor in keeping laboratory spaces safe for building occupants. Depending on the types of chemicals being stored, handled, used and dispensed in a space, rooms may have both general and hazardous exhaust.

General exhaust: This “room ventilation” is typically higher for laboratory spaces relative to spaces that do not store chemicals (such as offices). Ideally, mechanical ventilation in labs will have rates of 4-6 air changes per hour or 1 cubic feet per minute per square feet of laboratory space. This ensures that hazardous vapors or asphyxiants (from gases) are being removed from the occupied space and replenished by uncontaminated air.

Hazardous exhaust: Laboratories that consistently dispense and use toxic, flammable, corrosive, oxidizing and other hazardous materials often use fume hoods or gas cabinets to remove the hazardous vapors. Hazardous exhaust is not typically shared with room exhaust, nor is it recirculated. Hazardous exhaust is exhausted directly to the exterior of the building. Certain chemicals, such as concentrated perchoric acid, require special hoods. Highly toxic gases are required to be stored in gas cabinets or exhausted enclosures.

- More than 6 feet (1829 mm) above grade plane; or

-

Compliance

Compliance

RSS Chemicals – Control Area/MAQ/HMIS reports

Note: this is highly dependent on accurate inventories and correctly assigned building attributesToolbox of solutions from MAQ TF report

-

Hazard Categories

Hazard Categories

The California Fire Code (CFC) regulates hazardous materials that pose physical or acute health hazards. Materials are classified according to their CFC definitions for MAQ and regulatory purposes. These definitions are not always in alignment with OSHA definitions, which are based on the United Nation’s Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

Per CFC, chemical mixtures shall be classified with hazards of the mixture as a whole. Mixtures of hazardous materials shall be classified in accordance with nationally recognized reference standards; by an approved qualified organization, individual, or Safety Data Sheet (SDS); or by other approved methods.

California Fire Code Physical hazards include (see definitions in Chapter 2 of the CFC):

- Combustible dust

- Combustible fibers

- Combustible and Flammable Liquids

- Cryogenic fluids

- Explosives

- Flammable gases

- Flammable solids

- Inert compressed gases

- Organic peroxides

- Oxidizers

- Oxidizing gases

- Pyrophorics

- Unstable (reactives)

- Water reactives

California Fire Code Health hazards include (see definitions in Chapter 2 of the CFC):

- Corrosives

- Highly toxics

- Toxics

-

Occupancy Type

Occupancy Type

Occupancy classification refers to the formal designation of the primary purpose of the building, structure or portion thereof. These classifications are based on the nature of the hazards and risks to building occupants generally associated with the intended purpose of the building or structure.

Occupancy Classifications in California include:- Assembly: Group A (examples: lecture hall, concert hall, library, stadium)

- Business: Group B (examples: office, laboratory, professional services)

- Organized Camps: Group C (organized camp)

- Educational: Group E (examples: school or space used for educational purposes through 12th grade)

- Factory and Industrial: Group F (examples: metal or wood shop, photographic film development studio)

- High Hazard: Group H (examples: chemical storage room, flammable liquid dispensing room, semiconductor fabrication room)

- Institutional: Group I (hospital, jail, nursing home)

- Laboratory: Group B (unless Group L or Group H) (examples: lab constructed as Group B)

- Laboratory: Group L (examples: lab constructed as Group L)

- Mercantile: Group M (examples: market, retail store)

- Residential: Group R (examples: dorm, apartment, hotel, residential care facility)

- Storage: Group S (examples: warehouse, parking garage)

- Utility and Miscellaneous: Group U (examples: greenhouse, barn, agricultural building)

All of the above occupancy classifications are present across UC Campuses and Health Centers.

There are different MAQ requirements depending on the type of occupancy. For example, Group H occupancies are constructed to account for certain types of hazardous materials and can therefore safely store very high quantities of those chemicals. Group M and S occupancies, when certain storage and packaging requirements are met, can store larger quantities of hazardous materials. Group B laboratories can be more restrictive than Group L laboratories, particularly on higher floor levels. See example below of MAQ percentage per floor for Group B control areas (Table 414.2.2) vs. Group L laboratory suites (Table 453.7.2.1) (per California Building Code):

For detailed definitions of occupancies, see Chapters 3 and 4 of the California Building Code. Keep in mind that occupancy classifications have changed over the years and older buildings may have different occupancy types that are not reflected in the current California Building Code.

-

Physical State

Physical State

The state of matter (solid, liquid, gas) for an individual chemical can affect the hazard risk. For example, gases cannot be easily contained in an accidental release. Therefore, there are additional restrictions on the storage and use of certain gases such as toxic or pyrophoric gases. The Fire Code regulates materials separately based upon physical state. It is critical to correctly assign containers in RSS Chemicals to the correct physical state. MAQ reporting is typically in units of pounds, gallons and cubic feet. RSS Chemicals is designed to convert volumes from metric or other units into required Fire Code units of measurement.

-

Storage vs. In-Use

Storage vs. In-Use

Storage of hazardous materials is defined and used in multiple ways in the Fire Code.

Definitions:

- Storage, Hazardous Materials. The keeping, retention or leaving of hazardous materials in closed containers, tanks, cylinders, or similar vessels; or vessels supplying operations through closed connections to the vessel.

- Closed container. A container sealed by means of a lid or other device such that liquid, vapor or dusts will not escape from it under ordinary conditions of use or handling.

- Use (Material). Placing a material into action, including solids, liquids and gases.

- Closed system. The use of a solid or liquid hazardous material involving a closed vessel or system that remains closed during normal operations where vapors emitted by the product are not liberated outside of the vessel or system and the product is not exposed to the atmosphere during normal operations; and all uses of compressed gases. Examples of closed systems for solids and liquids include product conveyed through a piping system into a closed vessel, system or piece of equipment.

- Open system. The use of a solid or liquid hazardous material involving a vessel or system that is continuously open to the atmosphere during normal operations and where vapors are liberated, or the product is exposed to the atmosphere during normal operations. Examples of open systems for solids and liquids include dispensing from or into open beakers or containers, dip tank and plating tank operations.

For hazardous materials, there is a notable difference in MAQs for chemicals in storage vs. in use.

Storage

In Use - Closed

In Use - Open

-

Quantities of Hazardous Materials

Quantities of Hazardous Materials

Each chemical (hazardous material) has unique physical and health hazards. Some chemicals have multiple hazards. For example, acetic acid is both flammable and corrosive.

Maximum allowable quantities (MAQs) are determined as an aggregate quantity of a hazardous materials per hazard class and physical state in a single control area. Each control area has separate MAQ limits, based upon building features such as floor level and automatic fire sprinkler coverage.

Here is an example of how MAQs are determined within a control area. If the floor of this building is a single control area, then each of the labs’ chemical quantities will be combined in aggregate to determine the MAQ for each hazard category.

In this example, the aggregate quantity of flammable liquids exceeds the MAQ and is not in compliance.

Approved Storage

Storage is also used to refer to hazardous materials that are stored within approved hazardous materials storage cabinets, flammable liquids storage cabinets, gas cabinets, and more. RSS Chemicals refers to this as Approved Storage. Chemicals that are stored in approved storage cabinets, day boxes, gas cabinets, gas rooms, exhausted enclosures or in listed safety cans may increase MAQs for certain hazard categories. In addition, highly toxic gases are not permitted in any quantity unless they are stored within approved gas cabinets or exhausted enclosures.

Approved Storage per California Fire Code (CFC) would include one of the following, specific to the type of material being stored: Note: Per CFC, cabinets must be self-closing and self-latching. There are many cabinets out there which close manually and are not considered approved.

-

Exhausted Enclosures

Exhausted Enclosures

These are suitable for gases (inert, flammable, oxidizing, reactive, pyrophoric, toxic, highly toxic, or corrosive). They are not designed for cryogenic fluids. These may be suitable for highly toxic solids and liquids in Group H-8 occupancies (prior to 2007).

Construction. Exhausted enclosures shall be of noncombustible construction.

Ventilation. Exhausted enclosures shall be provided with an exhaust ventilation system. The ventilation system for exhausted enclosures shall be designed to operate at a negative pressure in relation to the surrounding area. Ventilation system shall be installed in accordance with the California Mechanical Code. Ventilation systems used for highly toxic and toxic gases shall also comply with the following:

1. The average ventilation velocity at the face of the enclosure shall be not less than 200 feet per minute (1.02 m/s) with not less than 150 feet per minute (0.76 m/s).

2. Exhausted enclosures shall be connected to an exhaust system.

3. Exhausted enclosures shall not be used as the sole means of exhaust for any room or area.

Fire-extinguishing system. Exhausted enclosures where flammable materials are used shall be protected by an approved fire-extinguishing system.

-

Flammable Liquid Storage Cabinets

Flammable Liquid Storage Cabinets

These are suitable for flammable and combustible liquids.

Design and Construction. Shall be in accordance with the following:

Materials. Cabinets shall be listed in accordance with UL 1275, or constructed of approved wood or metal in accordance with the following:

1. Unlisted metal cabinets shall be constructed of steel having a thickness of not less than 0.044 inch (1.12 mm) (18 gage). The cabinet, including the door, shall be double walled with 1 ½-inch (38 mm) airspace between thew walls. Joints shall be riveted or welded and shall be tight fitting.

2. Unlisted wooden cabinets, including doors, shall be constructed of not less than 1-inch (25 mm) exterior grade plywood. Joints shall be rabbeted and shall be fastened in two directions with wood screws. Door hinges shall be of steel or brass. Cabinets shall be painted with an intumescent-type paint.

Labeling. Cabinets shall be provided with a conspicuous label in red letters on contrasting background that reads: “FLAMMABLE – KEEP FIRE AWAY.”

Doors. Doors shall be well fitted, self-closing and equipped with a three-point latch.Bottom. The bottom of the cabinet shall be liquid tight to a height of 2 inches (51 mm).

Capacity. The combined total quantity of flammable and combustible liquids in a cabinet shall not exceed 120 gallons (454 L).

-

Gas Cabinets

Gas Cabinets

These are suitable for gases (inert, flammable, oxidizing, reactive, pyrophoric, toxic, highly toxic, or corrosive). They are not designed for cryogenic fluids.

Construction. Gas cabinets shall be constructed with the following:

Ventilation. Gas cabinets shall be provided with an exhaust ventilation system. The ventilation system for gas cabinets shall be designed to operate at a negative pressure in relation to the surrounding area. Ventilation system shall be installed in accordance with the California Mechanical Code. Ventilation systems used for highly toxic and toxic gases shall also comply with the following:

1. The average ventilation velocity at the face of gas cabinet access ports or windows shall be not less than 200 feet per minute (1.02 m/s) with not less than 150 feet per minute (0.76 m/s) at any point of the access port of window.

2. Gas cabinets shall be connected to an exhaust system.

3. Gas cabinets shall not be used as the sole means of exhaust for any room or area.

Maximum number of cylinders per gas cabinet. The number of cylinders contained in a single gas cabinet shall not exceed three. (Note: for toxic and highly toxic gases, there is an exception for cabinets containing cylinders not exceeding one pound (0.454 kg) where net contents are allowed to contain up to 100 cylinders).

-

Hazardous Materials Storage Cabinets

Hazardous Materials Storage Cabinets

These are suitable for most solid and liquid hazardous materials, with the exception of gases and flammable liquids.

Construction. The interior of the cabinets shall be treated, coated or constructed of materials that are nonreactive with the hazardous materials stored. Such treatment, coating or construction shall include the entire interior of the cabinet. Cabinets shall either be listed in accordance with UL 1275 as suitable for the intended storage or constructed in accordance with the following:

1. Cabinets shall be of steel having a thickness of not less than 0.0478 inch (1.2 mm) (No. 18 gage). The cabinet, including the door, shall be double walled with a 1 ½ inch (38 mm) airspace between the walls. Joints shall be riveted or welded and shall be tight fitting. Doors shall be well fitted, self-closing and equipped with a self-latching device.

2. The bottoms of cabinets utilized for the storage of liquids shall be liquid tight to a minimum height of 2 inches (51 mm).

Warning markings. Cabinets shall be clearly identified in an approved manner with red letters on a contrasting background to read: HAZARDOUS – KEEP FIRE AWAY

-

Safety Cans

Safety Cans

Safety cans shall be listed in accordance with UL 30 where used to increase maximum allowable quantities per control area of flammable or combustible liquids in accordance with the MAQ Table.

Resources

- Additional Resources

-

Software

Risk and Safety Solutions MAQ Information

Need help? Contact Risk & Safety Solutions by email (service@RiskandSafetySolutions.com) or visit the RSS Support website.

Chemicals Dashboard

Infographics

- Appendix D: Flowchart of MAQ Management (pdf)

- MAQ Accuracy Hurdles (pdf)

- Flowchart of MAQ Management (pdf)

Maximum Allowable Quantities (MAQ) Dashboard (MAQ Solution)

- MAQ FAQs

- MAQ Tutorial | RSS (pdf)

- MAQ Q&A | RSS (webinar)

- View MAQ Reports (pdf)

Webinars (RSS Webinars)

- Fire Code Chemical Hazard Classification Webinar (April 24, 2024)

View Recording - RFID Barcode Best Practices Webinar (July 18, 2023)

View Recording - MAQ Informational Q & A with Risk and Safety Solutions (January 22, 2022)

View Recording

-

Training & Information

Training & Information

Regulatory Information

- California Fire Code

- MAQ Tables (CFC)

- In California we abide by the California Fire Code; which supersedes other regulations.

International Code Council (Digital Codes)

Maximum Allowable Quantities (MAQ) Chemical Task Force

The Task Force produced recommendations that will facilitate compliance with MAQs – four specific to each UC location and six for systemwide implementation by the UC Office of the President. The UC Chemical Storage Maximum Allowable Quantities Task Force Report and Recommendations (redacted to maintain Attorney Client Privilege) is publicly accessible. These recommendations consider challenges such as aging infrastructure, limited resources, and evolving research programs.

Chemical Management Safety Center of Excellence

- Megan Hall, Deputy Fire Marshal - Hazardous Materials (mchall@berkeley.edu)

- Risk Summit 2023 | A new Approach to Chemical Management - MAQs Deciphered (pdf)

- California Fire Code

Roles

-

Building/Space Manager

Building/Space Manager

How do MAQs affect my building?

Fire Code Maximum Allowable Quantities (MAQs) are limits on types and quantities of hazardous materials (chemicals) that can safely be stored in buildings. MAQ limits are dependent on how the building was constructed, whether it has full automatic fire sprinkler coverage, and other variables such as which floor/level chemicals are being stored and used. MAQ limits are more restrictive for highly hazardous chemicals.

How do MAQs affect space assignments for chemical users in my building?

Fire Code Maximum Allowable Quantities (MAQs) vary tremendously on building attributes such as sprinkler coverage, fire-resistant rated construction, and where hazardous materials are being stored and used. Upper floors (higher than 3rd story) are more challenging for occupants to evacuate during emergencies. These upper levels are also more challenged for first responders to access, therefore the MAQ limits are reduced on higher levels relative to the first floor.

For building managers responsible for assigning new faculty to spaces, it is prudent to discuss the limitations of that space with EH&S or the Campus Fire Marshal prior to space assignments. For example, synthetic chemistry research or users of toxic gases will be severely restricted on upper floors of most buildings. -

Campus Fire Marshal

Campus Fire Marshal

You are responsible for identifying control areas and/or lab suites for the buildings on your campus. This can be done via identifying fire-resistant rated construction from record drawings. Fire barriers used to separate control areas should be field verified for integrity. For buildings constructed prior to 2007, Fire Marshals have the option to apply the 2001 California Fire Code where the 4-control area concept is used. (see OSFM bulletin in References).

RSS Chemicals

Assumptions for each building: Within RSS Chemicals, default settings are:

- 2016 code year

- Building is not equipped throughout with an automatic fire sprinkler system

- each floor is a separate, single control area

- B-occupancy

- each floor is the first story above grade plane

- Hazardous materials are not in approved storage

If all of the above are correct, no changes are needed to set up control areas.

Refer to RSS MAQ Tutorials for information on how to update these items :

• Code year

• Sprinkler coverage

• Floor level relative to grade plane

• Occupancy type (done separate per control area)

• Creating control areas and assigning rooms to control area

• Approved storage (per hazard category and physical state) -

Environmental Health & Safety (EH&S)

Environmental Health & Safety (EH&S)

EH&S staff are typically managing chemical inventories for their campus or health center. These individuals should be very familiar with RSS Chemicals. EH&S often acts as the liaison between chemical users and regulatory agencies and the Campus Fire Marshal, therefore they need to be familiar with the objectives of MAQ compliance and how they impact chemical users.

- Review the report

- Identify a program administrator (main POC)

- Create a plan for ensuring chemical inventories are updated/accurate using RSS Chemicals

Building attributes assessment

- Work with Campus Fire Marshals (CFMs) to identify control areas

- CFMs must ensure each building has appropriately assigned sprinkler coverage, occupancy type, and floor levels.

Chemical Inventory management

- Implement a labeling system (barcode/RFID)

- Coordinate with laboratories and Facilities to use RSS Chemicals for all spaces storing chemicals

- Coordinate laboratory cleanups

- Increase disposal of unwanted chemicals

- Promote sustainability (recycling) of unused chemicals

4. Review MAQ reports per building and control area (Note: this has limited value unless control areas and chemical inventories are accurate)

5. Develop an MAQ Management Plan with CFM- Conduct a risk assessment (jointly)

- Identify significant problem areas and potential solutions

6. Work with departments to correct MAQ problems

- Educate researchers and chemical owners on MAQ compliance

- Provide different solutions for situations where MAQs are exceeded

- Identify approved storage for particular hazard classes

- Update inspection checklists to spot check chemical inventories and to inspect fire barriers

7. Ensure users complete training

8. Explore alternate funding routes (e.g., BSAS)

9. Provide metrics for use in annual report

-

Executives (Chancellors, Vice Chancellors, Deans, Department Chairs)

Executives (Chancellors, VCs, Deans, Department Chairs)

President Drake issued a Directive on California Fire Code Maximum Allowable Quantity (MAQ) Compliance (link) with a timeline for completion (by 2030). Executive Officials from each campus are responsible for assuring their campus buildings are on track towards MAQ Compliance on or before this date.

Fire Code Maximum Allowable Quantities (MAQs) are limits on types and quantities of hazardous materials (chemicals) that can safely be stored and used in buildings. These limits apply to all buildings on UC property. MAQ limits are dependent on how the building was constructed, whether it has full automatic fire sprinkler coverage, and other variables such as which floor chemicals are being stored and used. MAQ limits are more restrictive for highly hazardous chemicals and for chemicals stored and used on upper floors (greater than 3 stories). These limits can have a significant impact on existing research laboratories. In many cases, researchers will be asked to reduce the number of chemicals they are currently storing in their labs in order to become compliant with the California Fire Code. EH&S and the Campus Fire Marshal can provide guidance on the MAQ Initiative.

-

Planning, Design, & Construction

Planning, Design, & Construction

Fire Code Maximum Allowable Quantities (MAQs) are limits on types and quantities of hazardous materials (chemicals) that can safely be stored and used in buildings. MAQ limits are dependent on how the building is constructed, whether it has full automatic fire sprinkler coverage, occupancy type, and other variables such as which floor/level chemicals are being stored and used. For all new projects (new building or TI project), inquire as to whether or not any hazardous materials will be stored in the new space. Labs, shops, storage facilities, diesel generators, research support buildings, energy storage, facilities supporting custodial or maintenance are some examples of spaces which may contain hazardous chemicals.

In the earliest planning phases, discuss any planned chemical storage with your Campus Fire Marshal. They can provide guidance on the most appropriate type of building and/or occupancy type for planned chemical usage. Hazardous Materials Inventory Statements (HMISs) will be required prior to submittal of new projects.

Fire Code Maximum Allowable Quantities (MAQs) vary tremendously on building attributes such as sprinkler coverage, fire-resistant rated construction, and where hazardous materials are being stored and used. Upper floors (higher than 3rd story) are more challenging for occupants to evacuate during emergencies. These upper levels are also more challenged for first responders to access, therefore the MAQ limits are reduced on higher levels relative to the first floor.

-

Procurement

Coming Soon.

-

Project Management

Coming Soon.

-

Researchers (P.I.s, Post-Docs, Graduate Students)

Researchers (PIs, Post-Docs, Graduate Students)

What are MAQs and how do they impact me?

Fire Code Maximum Allowable Quantities (MAQs) are limits on types and quantities of hazardous materials (chemicals) that can safely be stored in buildings. MAQ limits are dependent on how the building was constructed, whether it has full automatic fire sprinkler coverage, and other variables such as which floor/level chemicals are being stored and used. MAQ limits are more restrictive for highly hazardous chemicals and on upper floors (above 3rd story).

MAQ limits for your lab are impacted by your specific building and lab space. For many buildings, you share the MAQ limits with other labs on the same floor as you. In other spaces, your lab may be surrounded on all sides by fire-resistant rated construction, keeping it as a separate “control area” from neighboring labs. If your lab is separated, MAQ limits are restricted to your individual control area.

Upper floors (higher than 3rd story) are more challenging for occupants to evacuate during emergencies. These upper levels are also more challenged for first responders to access, therefore the MAQ limits are reduced on higher levels relative to the first floor.

In many cases, your lab will need to reduce chemical quantities in order to be compliant with the California Fire Code. Operationally, this could mean lab cleanouts and removal of older chemicals, more frequent orders of common chemicals in smaller quantities (rather than bulk), sharing common chemicals within your lab (rather than each researcher having their own container), and reliance on stock rooms or re-use facilities for some chemicals.

Contact EH&S or your Campus Fire Marshal to learn more about MAQ limits for your lab and control area.

Locations

Communications and resources related to MAQ efforts at each location.